- Home

- Products

-

- ERW Tube Mills The tube mill is the best choice for the production of welded steel pipe like API (American Petroleum Institute) pipe, OCTG (Oil Country Tubular Goods) pipe, exhaust pipes for vehicles, strucutral pipes and more.

-

- (Direct Forming to Square) ERW Tube Mills

Great flexibility and possibility for modifying tube dimensions without having to change the rollers during forming, welding, sizing and flattening for any sizes included within the equipment setting range.

Extreme reduction of equipment set up time.

-

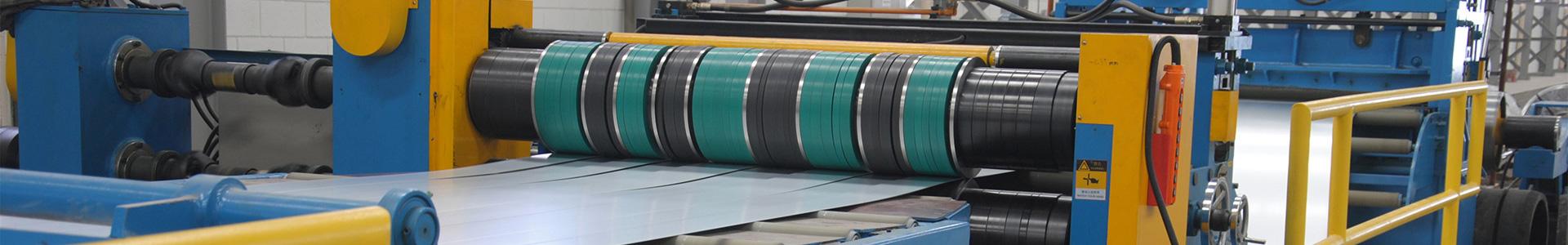

- Slitting Line The slitting line is used to slit coiled steel strips into several narrow strips in specific sizes. The slit strips are then rewound into coils, from which welded pipes, cold-formed sections, and presswork are manufactured.

-

- Cut To Length Line This metal cut to length production line features hydraulic adjustment and the finished steel plates have uniform width and flatness, therefore, the final products made of steel plates have a better appearance and quality.

-

- Single Unit in Tube Mill We also supply different materials for customers to choose from: Cr12, 9Cr2Mo, Cr12MoV, Cr12Mo1V1, H13, High Cr Alloy, and more.

-

- TIG Tube Mills TIG tube mills are stainless steel tube production equipment that utilizes a TIG (tungsten inert gas welding) method. Tubes produced using this equipment feature a diameter range of Ф6~Ф219mm with maximum wall thickness of 4mm.

-

- JCOE Pipe production line This tube mill uses a progressive bending process, featuring an evenly distributed forming stress, high dimension uniformity, infinite size variation & wide product range, and a high flexibility.

- No.8 Xingbei Street, Shiyan Road, Shijiazhuang, Hebei

- +86-311-888-33011

- ERW Tube Mills

-

Round, Square, Rectangular Tube

- (Direct Forming to Square) ERW Tube Mills

- Slitting Line

- Cut To Length Line

- Single Unit in Tube Mill

- TIG Tube Mills

- JCOE Pipe production line

Products

- CNC Workshop

- About Us

Quick Link